Perforated aluminum panel production process basic description: 1, is to use clean water to rinse, the arc aluminum sheet base material of the above clear clean all dust.

2, again use alkaline cleaning arc aluminum sheet base material, alkaline materials can effectively dissolve arc aluminum sheet base material above all kinds of oil, add clean water can’t remove the stains.

3, reoccupy clear water dropped the residual alkali cleaning, ready for the next working procedure.

4, using acidic solution of curved aluminum sheet base material cleaning, again to wash arc aluminum sheet base material react with acid solution on the surface of the residue.

5, with water to clean again arc aluminum sheet base material.

6, the chromizing processing arc aluminum sheet base material.

7, with clear water after the chromizing arc aluminum panel of base material for cleaning.

8, again the perforated aluminum panel with protective film packaging complete play a protective role.

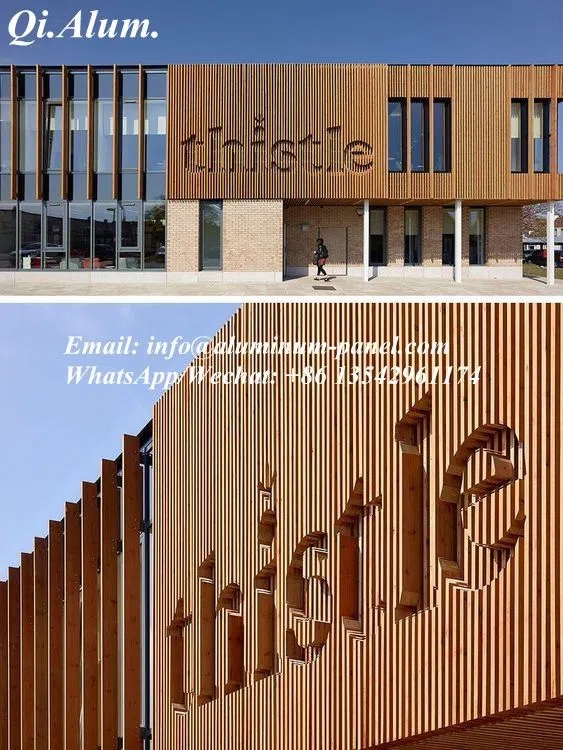

Carved Aluminum panel can provide a solid and reliable outdoor solution for both low-rise and high-rise buildings. The system is designed to withstand high wind pressure, as well as corners, roofs and other special corners. The plates can be treated with high-performance fluorocarbon coating technology, and the optional color is rich, with excellent scratch resistance, corrosion resistance and UV resistance.

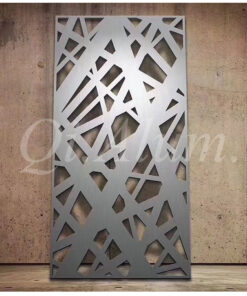

Carving aluminum panel as a carving art, need exquisite exquisite craft. Now more and more architectural designers incorporate hollowed out into architectural decoration, which not only enriches decorative art, but also enriches people’s living space. Carved aluminum panel can continue to extend the plane plate into the sense of space, with light, breathable, shaping the role of decorative style.

Different patterns, the size of the dense hole change collocation makes the surface dynamic, combined with different shape environment for irregular processing, the other line is more bright, elegant, breaking through the traditional concept of modeling, more suitable for a variety of modern senior clubs, office and other occasions, for the dynamic fashion family to open up endless thinking space, is a practical and beautiful new form of decoration.

Qi.Aluminum introduced the new engraving and hollowing cutting technology, the aluminum plate according to the designer’s graphics for cutting, high accuracy, no damage to the surface, processing products in the cooling state of cutting, no deformation, smooth cutting surface does not sting, no burr, small cutting slit, fine process, high accuracy, good quality, Suitable for a variety of high degree, complex map, large map, special-shaped map, curve and other complex pattern cutting.

Carved hollow aluminum veneer can be processed into a variety of specifications and different shapes of the special-shaped aluminum plate, according to the requirements of designers, made of a variety of ceiling, curtain wall, pillars and other patterns. Aluminum plate substrate adopts 1100H24, 1060H24, 3003H24, 5005H24 curtain wall special single-layer aluminum alloy plate.

Common specifications:

Length <5000mm, width <1500mm (other specifications can be customized).

Common thickness:

1.5mm, 2.0mm, 2.5mm, 3.0mm(other specifications can be customized).

Advantages:

1, exquisite appearance, rich patterns, high processing accuracy to meet the decorative requirements of different styles.

2, A class fire prevention, corrosion prevention, moisture-proof.

3, anti-rust, anti-damage, anti-UV, anti-mold.

4, long service life, can keep 10-15 years without discoloration, no deformation.

5, strong plasticity, can be processed into a variety of complex modeling.

6, green environmental protection, recyclable, protect the ecological environment, reduce the waste of material resources.

Recommended application:

1. Sealing of walls, beams, columns, balconies, corridors, sides of escalators and fireproof rolling curtains inside buildings

2. Airport terminal and high-speed rail station

3, sports venues, shopping malls, schools, hospitals

4. Lecture Hall, conference room, Opera House

5. Office and hotel lobby

FAQs

Q: How long can i get a quote?

A: The quotation can be provided no longer than 24 hours on condition that we know all detailed requirements.

Q: What is the payment term?

.A: T/T or L/C.

Q: Do you offer sample?

A: Free sample can be offered. Delivery can be arranged within 48 hours.

Q: Where have you sold your products?

A: Nigeria, Africa, Middle East, Thailand, etc.

Q: Can i buy installation accessories from you?

A: Yes, we provide wet wall and dry wall system installation accessories.

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!