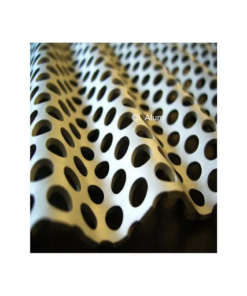

Perforated aluminum corrugated metal mesh building facades construction cladding

The perforated aluminum corrugated panel is processed with a perforated pattern by carving before the corrugated shape is made, and then bent to make a corrugated shape.In recent years, aluminum corrugated wavy walls have become more and more popular in interior design space, and are common in many projects designed by designers. The unique shape of aluminum corrugated wave panel has set off a new wave in the design circle, and has been favored by major designers. Because of its light weight, good rigidity and high strength, its installation and construction are convenient and fast, this material is not easy to stain, and has a strong self-cleaning property. It is also a 100% recyclable environment-friendly material, so it has become more and more popular in recent years.

The corrugated panel is different from the profile corrugated panel, which is not formed by extrusion, but by die stamping. The thickness of profile corrugated panel is usually small, generally less than 2MM, but the thickness of punched corrugated panel can be 2MM, 2.5MM, 3MM, 3.5MM, 4MM, etc. they are all commonly used thicknesses. The size of the panel can also be relatively large, the width can reach 600 mm, and the length can reach 2~3000 mm. The panel of the profile can only be generally small, and it needs to be assembled to get a larger panel.

Advantages:

1.High plasticity, can be made as flat,camber or spherical shape.

2.Wide range of colors

- Excellent in weather fastness and corrosion resistance.

- Good fireproof and waterproof property.

- Even coating, various colors.

6.Easy to process ,easy to maintain.

Contact: