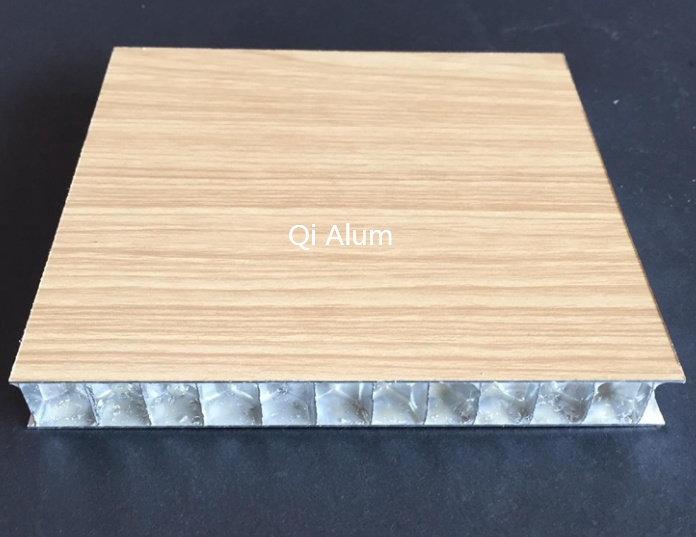

1, high strength, wind pressure performance prominent. Honeycomb aluminum plate originated in the aerospace industry, can withstand the harsh climate and environment. 12mm honeycomb board can carry more than 8500Pa wind pressure load, 25mm thick honeycomb aluminum plate can carry 12000Pa wind pressure load (with national professional testing report).

2, super flat. Honeycomb aluminum is a perfect composite structure, the middle of the honeycomb core for the panel and the floor to increase the number of equal height, uniform support, the average error of 0.3mm-0.8mm. Large plate use, without adding stiffeners.

3, green, environmental protection, energy saving. Because of its unique composite structure, honeycomb panels with insulation, sound insulation (a national professional test report) performance, the state advocates of environmental protection, energy-saving materials.

4, light weight: honeycomb board is a combination of light material cleverly combined with 3-5kg per square meter, greatly reducing the load on the building.

5, easy installation, fast. Honeycomb aluminum plate is based on the size of the field design, in the factory after cutting, folding, composite, curved arc and other procedures processing.

6, stunning visual effects: ① honeycomb aluminum substrate coating is the use of high-tech roller coating, not easy to produce visual color. ② honeycomb aluminum surface coating with KYNAR500 fluorocarbon resin paint, its main components: polyvinylidene fluoride resin, referred to as PVDF resin. PVDF resin in the fluorocarbon coating resin content of 75%.

7, coating performance: anti-ultraviolet: anti-powder and nuclear radiation function, to maintain its color gloss for several decades. Chemical resistance: acid, alkali resistance, resistance to air pollution, acid rain attack. Corrosion resistance: anti-oxidation, anti-high humidity and corrosion particles, can withstand long-term harsh environment. Paint film household good mechanical properties: a strong impact resistance, strong wear resistance and superior paint flexibility. Easy to clean

8, substrate: 12mm thick honeycomb aluminum plate is selected AA3003 / 3005H44 substrate, high tensile strength.

3 series aluminum alloy, also known as aluminum-manganese alloy, manganese content of 1-1.5%, is the application of a wide range of rust-proof aluminum alloy series, 3-series aluminum alloy strength than pure aluminum alloy, although not heat treatment to strengthen the performance , But in the cold processing (cold rolling mill rolling) and annealing process has a good plasticity, because it has good corrosion resistance and welding performance, can be used in many industries, such as building decoration industry, electronics manufacturing , Automobile manufacturing and so on.

3 series of aluminum alloy commonly used in the main grades are 3003 aluminum, 3004 aluminum, 3104 aluminum, 3005 aluminum, 3105 aluminum and so on. The larger amount is 3003 grade aluminum alloy, 3003 aluminum plate for processing, rust good, can be painted in the original aluminum surface color paint, made of decorative curtain wall panels, and indoor ceiling with aluminum ceiling, but also After the pressure tile machine bending production of roof aluminum tiles, light and durable, life is better than steel. Therefore, our company wind buckles are 3 series of aluminum as raw materials.

3 series of aluminum plate hardness than pure aluminum plate 10% -20% higher, cold work to improve strength, at room temperature conditions have good formability, solubility and corrosion resistance, excellent welding performance.

3 series of aluminum prominent features, is its good rust, corrosion resistance. As a result of the addition of manganese, 3 series aluminum plate has a higher corrosion resistance than 1 series aluminum plate, and has good corrosion resistance to atmospheric, fresh water, sea water, food, organic acid, gasoline, neutral inorganic salt solution. The corrosion resistance in the dilute acid is also good, so it can be applied to many special environments.

1000 series on behalf of 1050 1060 1070 1000 series aluminum plate is also known as pure aluminum, in all series 1000 series is the largest amount of aluminum in a series. Purity can reach more than 99.00%. Because it does not contain other technical elements, so the production process is relatively simple, the price is relatively cheap, is the conventional industry commonly used in a series. Most of the current market circulation for the 1050 and 1060 series. (Including aluminum content of more than 99.9%) is mainly used for scientific experiments, chemical industry and special purpose. Application of high purity aluminum (aluminum content of more than 99.9%) is mainly used for scientific experiments, chemical industry and special purpose.